Improved ship engine reliability

Improved ship engine reliability

Large ships or vessels consists of heavy machinery prone to defects and failures. Failure of any machinery or component can incur heavy repair costs, labour costs and logistical costs. Untimely deliveries due to unplanned downtime also affect the revenues considerably.

To avoid unplanned equipment failure, the shipping industry has been employing a periodic or planned maintenance practice wherein inspection, component replacement and lubrication are performed at periodic intervals. This method prevents breakdown but is rather expensive. Preventive maintenance requires a large number of personnel along with availability of spare parts, which increase the holding costs. Also, routine maintenance also limits the availability of ships.

To prevent breakdowns as well as to limit the routine maintenance tasks, it is essential to monitor machines continuously, predict failures and perform maintenance only when necessary.

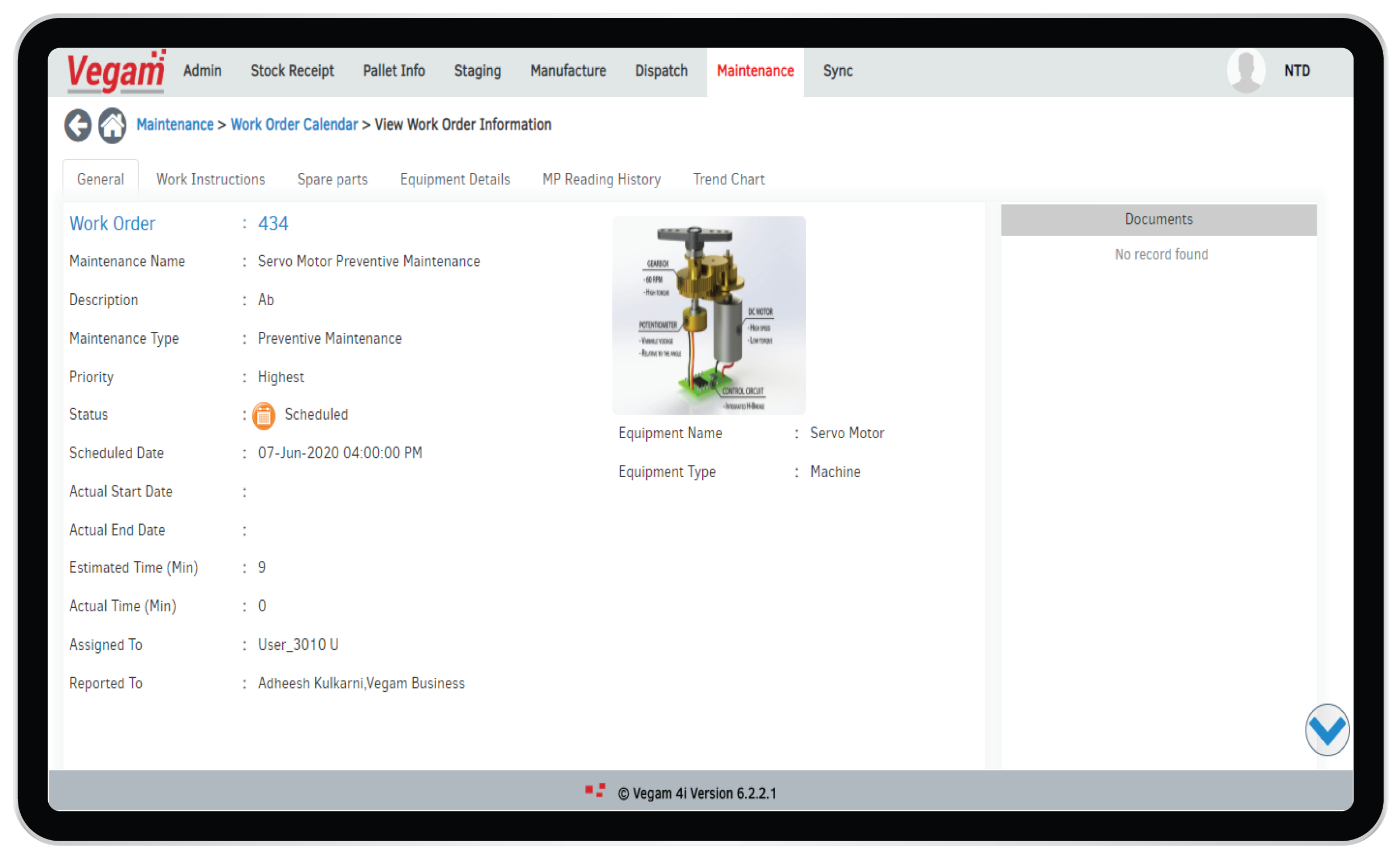

Vegam’s predictive maintenance platform along with smart IoT sensors enables continuous monitoring of shipping components. Machine failures and fault conditions can be predicted using predictive analytics, thus optimizing the whole maintenance in shipping industry.

Read more

AI/ML Driven Offline Prediction of engine failures

Predictive Maintenance

Large ships or vessels sail for a really long time and their engines involve heavy machinery with highly complex and critical components that keep the ships in the sea. It is highly critical that the ship engine run at an optimal running condition and any issues that may occur be predicted before the outcomes are life threatening.

Predict ship engine failures before they occur with vMaint4.0 Vegam Predictive maintenance solution, which has offline prediction. With Vegam platform, the maintenance team gets Industrial grade IP68 certified IoT sensor packaged maintenance management solution

- 5 years battery life

- Up to 25.6kHz frequency measured

- Mobile first solution

- Easy installation

- Improved engine reliability : Better planning and executing preventive maintenance helps prevent engine failures, monitor valve functioning and pumps with edge computing capabilities

- Predict Machine failures : Real-time condition monitoring and predictive maintenance helps in reducing downtimes and prevent unexpected engine failures. This in turn result in better efficiency of ship engine and can go longer without having to perform maintenance activities or engine failures.

Schedule a Demo

One of the leading Adhesive

manufacturers in Asia was able

to achieve

10% Improvement

in productivity.

Customer success stories

Enabling Smart Maintenance Operations in Automotive Component Manufacturing

Case Study Customer Profile Pioneer in Adhesive technologies Headquartered in Europe with Annual revenue over 20 Billion USD Well established

Reach out to us