Feature

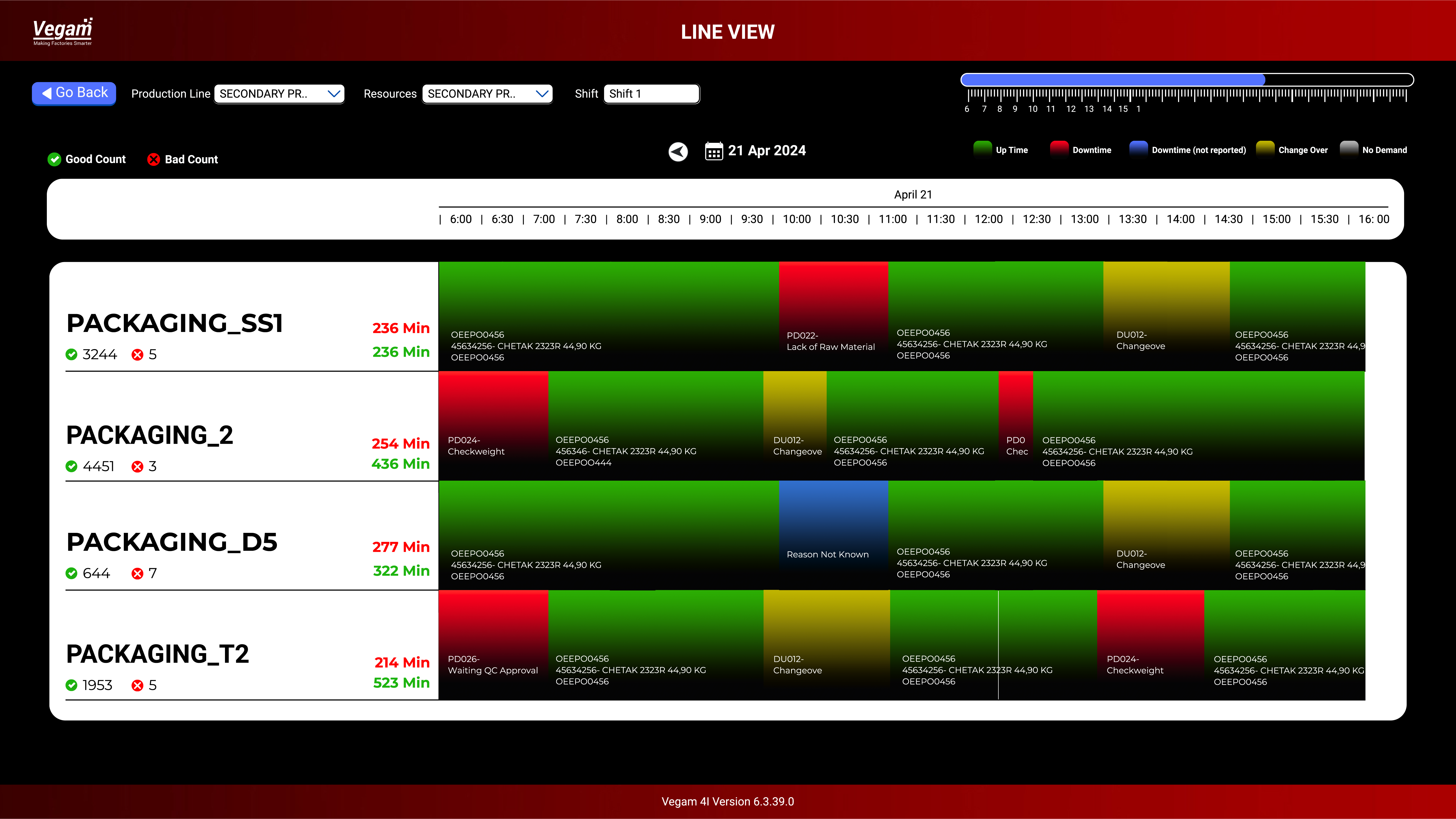

Global Downtime Visibility

Multi-Plant Benchmarking

Persona-Based Dashboards

Easily Configurable by Plant Staff

Expandable to MES

AI/ML Driven Actionable Insights

Increase OEE, Identify Downtime Patterns, and Improve Throughput with AI-Driven Analytics

Increase throughput by 10%

Identify the downtime patterns 10x faster

Real-time OEE analytics and downtime insights across every production line—powering operational excellence in 300+ factories worldwide

Upto 25% reduction in micro stoppages

Save $50K–$200K per Line Annually

Empower CI & Ops Teams with Role-Based Insights

Self-Configurable, No IT Dependency

Comprehensive Features Tailored for Manufacturers

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.

Role-specific views for operators, supervisors, managers, and CI teams.

Tailored to each plant’s functionality; no one-size-fits-all limitations.

Real-time OEE analytics and downtime insights across every production line—powering operational excellence in 300+ factories worldwide

Upto 25% reduction in micro stoppages

Save $50K–$200K per Line Annually

Empower CI & Ops Teams with Role-Based Insights

Self-Configurable, No IT Dependency

Additional Units Per Year

Additional Annual Value

In some cases, vMaxOEE replaced legacy OEE platforms across 16 lines due to lack of global downtime visibility and deeper analytics.

Global Downtime Visibility

Multi-Plant Benchmarking

Persona-Based Dashboards

Easily Configurable by Plant Staff

Expandable to MES

Turn your Factory into a Smart Factory

Contact us today to schedule a personalized demo and see how vMaxOEE can transform your operations.